Refurbishment of the Eiffel tower in Paris

With an area of about 400m², the third floor of the Eiffel tower receives close to 7 million visitors every year. The floor is subject to heavy traffic around the year, and is also exposed to high climatic constraints (rain, wind, heat etc.).

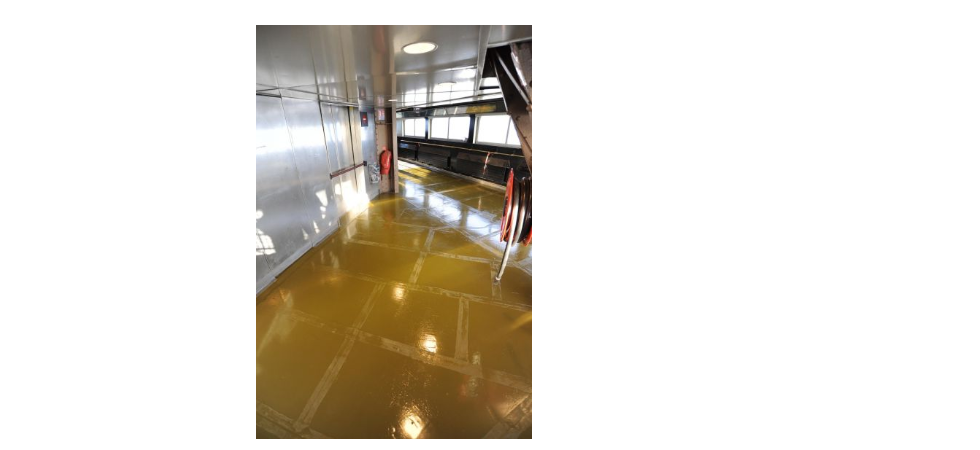

That is why safe movement in the building makes it necessary to have full control over the waterproofing system.

The work had to meet two major criteria:

- Use of a low weight product, as the architectural structure of the tower does not allow overloading, and completion of work in a week at the most, as closing off a floor led to significant financial losses in terms of tourist revenue.

Alsan® 400, liquid waterproofing that is adaptable and safe.

- In the case of the Eiffel tower, the elasticity and mechanical strength properties of Alsan® 400 coating meant it could be applied directly on metal. Alsan® 400 is single-component resin designed for structures that are walked upon and require heavy-duty added protection. The coating was capable of meeting all the structural requirements of the Eiffel tower.

Its easy application system made it possible to complete the job within a week.

On the first two days, the workers applied the first anticorrosion epoxy layer. Then they treated the plate joints with Alsan® Toile reinforcing scrim and Alsan® 500 Adhesive. That system limited movements and differences due to temperature variations, which make the metal expand. On days 3 and 4, the technicians applied two coats of Alsan® 400. On day 5, they installed a separating polyester felt membrane to protect the waterproofing. That membrane helped reinforce the system before the installation of non-slipping finishing metal plates.